The control process is the system that allows setting, measuring, matching, and tweak any business activities such as production, packaging, delivery, and more.

Controlling is an essential part of the management process.

In fact, without the control process, the entire management is obsolete. Because you will not be able to know how your plan is working, is it fully implemented?

Also, without control, you cannot actionable lead the workforce.

The control process is the functional process for organizational control that arises from the goals and strategic plans of the organization.

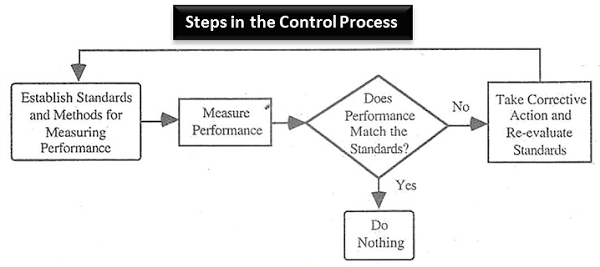

4 Steps of the Control Process are;

These steps are described below;

Establishing Standards and Methods for Measuring Performance

Standards are, by definition, simply the criteria of performance.

They are the selected points in an entire planning program at which performance is measured so that managers can receive signals about how things are going and thus do not have to watch every step in the execution of plans.

Standard elements form precisely worded, measurable objectives and are especially important for control.

In an industrial enterprise, standards could include sales and production targets, work attendance goals, safety records, etc.

In service industries, on the other hand, standards might include several times customers have to wait in the queue at a bank or the number of new clients attracted by a revamped advertising campaign.

Measuring the Performance

The measurement of performance against standards should be measured on a forward-looking basis so that deviations may be detected before their occurrence and avoided by appropriate actions.

Several methods are used for measuring the performance of the organization.

If standards are appropriately drawn and if means are available for determining exactly what subordinates are doing, appraisal of actual or expected performance is fairly easy.

But there are many activities for which it is difficult to develop accurate standards, and many activities are hard to measure.

It may be quite simple, for example, to establish labor-hour standards for the production of a mass-produced item, and it may be equally simple to measure performance against these standards, but in the less technical kinds of work.

For example, controlling the work of the industrial relations manager is not easy because definite standards cannot be easily developed.

The superior of this type of manager often relies on vague standards, such as the attitude of labor unions, the enthusiasm and loyalty of subordinates, the index of labor turnover and/or industrial disputes, etc. In such cases, the superior’s measurements are often equally vague.

Determining whether Performance Matches the Standard

Determining whether performance matches the standard is an easy but important step in the control process. It involves comparing the measured results with the standards already set.

If performance matches the standard, managers may assume that “everything is under control.” In such a case, the managers do not have to intervene in the organization’s operations.

Taking Corrective Action

This step becomes essential if performance falls short of standards and the analysis indicates that corrective action is required. The corrective action could involve a change in one or more activities of the organization’s operations.

For example, the branch manager of a bank might discover that more counter clerks are needed to meet the five-minute customer-waiting standard set earlier.

Control can also reveal inappropriate standards; in that case, the corrective action could involve a change in the original standards rather than a change in performance.

It needs to be mentioned that unless managers see the control process through to its conclusion, they are merely monitoring performance rather than exercising control.

The emphasis should always be on devising constructive ways to bring performance up to a standard rather than merely identifying a past failure.